Eliminates rags/clogs in wastewater pumps

Wealth of diagnostic information and pump data

Typical payback in months

Reduces operational callout costs

Improves electrical efficiency by up to 48%

Reduces pollution incidents

Minimal interruption to ‘live’ sites

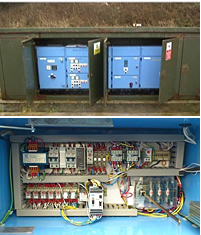

No new kiosks, replacement panels or construction works

Simple plug and play to any starter type

Left-click image and hold to rotate view

READ MORE

The multi-award-winning Deragger II from Clearwater Controls is the ideal solution for pump blockages and high energy costs – two of the biggest problems faced by the wastewater industry today.

The key feature of this low-voltage, electronic pump management system is real-time pump monitoring. This enables the patented technology in the Deragger II to identify and eliminate potential pump blockages, monitor the long-term condition of the pumps and reduce wear and tear caused by unbalanced loads.

Constantly Clean Impeller

By maintaining a clean impeller at all times, the Deragger II ends the time-consuming and costly necessity of manually lifting pumps, thus eliminating downtime and other costs associated with pump blockages. The reduction of environmental incidents, together with less electricity consumption, results in a lowered environmental impact and carbon footprint.

Measuring just 35mm in width, the din rail mounted Deragger II is designed to easily and quickly retrofit into existing control panels, making it the perfect solution for even the smallest pumping stations. It connects easily through plug and play, with In-line (DOL), Delta-wye (Star/Delta), Soft Start or VSD.

Full Diagnostic Information

Not only does the Deragger II automatically prevent blockages in real-time, it provides full pump diagnostic information. The wealth of pump performance data includes individual phase voltage, current and power to Kw/Hrs, run time and a number of start counters.

The device also logs daily average current and power consumption, plus average run cycle time. Three hundred and sixty-five days of data can be easily downloaded and analysed to show pump performance over a year, enabling the asset owner to determine maintenance or replacement schedules for the pumps.

FEATURES

Pump Protection:

- Phase loss

- Current imbalance

- Under/over current

- Under/over voltage

- Frequency out of range

Anti-ragging/clogging Prevention:

- Patented real-time monitoring and prevention

- Cleans pump on start up

- Timed clear trigger

- External trigger from PLC or low flow

- Trigger on 0-20mA analogue input

- Fully customisable clean cycle

Additional Apps:

- Wet well clean cycle

- Remote reset

- Odour control

- Batch/volume pumping

- Pump dry run protection

VIDEO

CASE STUDIES

Nigg WwTW (Kelda)

Since installing the Deragger II (Oct 2013):

- Despite the pumps ragging up several times daily prior to Deragger install, Nigg has since reported only a single ragging incident (one pump), which was due to a curtain-like material

Ross Point (Scottish Water)

Since installing the Deragger II (Apr 2011):

Since installing the Deragger II (Apr 2011):

No ragging issues since installation.

- No ragging issues since installation

- 35% reduction of electricity consumption

- Cost benefit of £8,112 in first year.

- Payback period of 5 months

Western Avenue (Los Angeles County Sanitation Districts)

Since installing the Deragger II (Nov. 2013):

- No ragging issues

- Reduction in electricity consumption by 4.5%

Lake Worth (City of Lake Worth)

Since installing the Deragger II (June 2014):

- No ragging issues since installation

- Increased flow rates

Strontian (Scottish Water)

Since installing the Deragger II (December 2012)

Since installing the Deragger II (December 2012)

- No ragging issues

- Ended expensive reactive callouts due to ragging at this isolated and difficult to reach site