PRESS RELEASE – Tuesday 23 October 2018

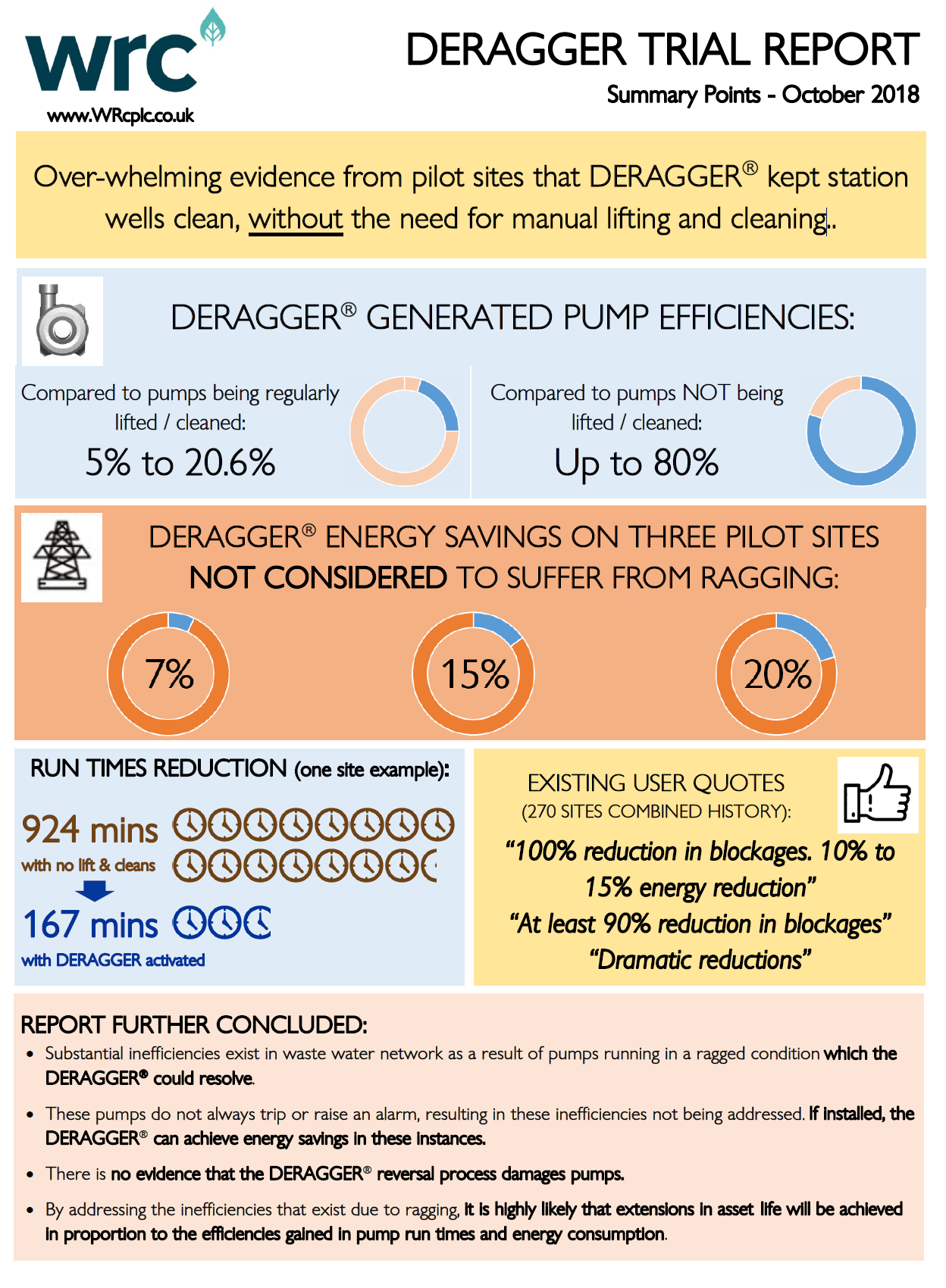

An independent trial into Clearwater Controls’ DERAGGER, a device that prevents blockages in waste water pumps, has found it cuts energy consumption by up to 80%, significantly reduces maintenance requirements and helps to extend asset life.

It is estimated that manually lifting and repairing pumps costs utility companies as much £160 million a year, with annual energy bills reaching £50million if not more.

The study delivered by the Water Research Centre (WRc) in conjunction with United Utilities and Wessex Water, found the DERAGGER to be an effective solution to these industry-wide challenges.

By analysing the torque of a pump, the device can detect items such as wet wipes and nappies in real time which could otherwise cause blockages. It can be triggered by even a few wet wipes and can automatically slow and reverse pumps to remove the potential blockage.

Running a pump when it is partially ragged, with an unstable current and unbalance impeller is known to cause significant wear and increase the amount of energy required.

During the 20-week trial, the DERAGGER minimised the need for manual cleaning at all testing sites. In one case, maintenance jobs decreased from nine to just one per month. At another site, no maintenance was required at all during a six-week period.

In addition, the DERAGGER reduced energy consumption by up to 80% for pumps which had not been recently cleaned and 20% for pumps which had been regularly lifted and cleaned.

Even in stations considered previously not to suffer from blockages, the DERAGGER achieved energy savings between 7% and 20%. With an estimate 181,000 wastewater pumps in the UK, the DERAGGER could significantly reduce overall energy usage across the sector. The report also found that efficiency savings could deliver extensions to asset life.

Simon Crompton, Clearwater Controls managing director said: “We’ve known for some time that our technology can significantly reduce blocked pumps, which account for an estimated 90% of all unplanned work carried out in the sewage system. These independent findings confirm that our device has the functionality to tackle the problem head on, by preventing blockages from occurring in the first place.

“On pumps that don’t regularly suffer blockages, while we were confident the DERAGGER would make a noticeable difference, we did not know the full extent. These findings show that even on these stations the DERAGGER can significantly decrease energy consumption and improve asset life, confirming our device truly is revolutionary.”

Dr Leo Carswell, Head of Technolgoy at WRc said “Our thorough analysis of the raw data from five DERAGGER trail sites clearly demonstrates the impact this innovation can have in the waste water sector. We found it to demonstrably reduce pump blockages, and also signfifcantly reduce energy consumption – even on sites considered to be at low risk of blockages.”

In 2017, Clearwater Controls received funding from UK Steel Enterprise, the regeneration arm of Tata Steel, to deliver research and bring the product to market.

A full copy of the WRc report can be found at: https://clearwatercontrols.co.uk/wrcreport/

A one-page summary of the results can be found by clicking here.

-ENDS-

Issued by BIG Partnership on behalf of Clearwater Controls. Hi-res images and interviews are available.

For more information please contact: Ashleigh Copeland, T: 0141 333 9585 M: 07808 330 153 E: ashleigh.copeland@bigpartnership.co.uk

Notes to editor: The DERAGGER was trailed by Water Research Centre (WRc), with the support of Clearwater Controls and employees of United Utilities and Wessex Water. Five pumping station sites were included in the trial. Four of these sites were wet wells and one was a dry well.